The technological revolution has disrupted manufacturing like no other industry. During the industrial revolution, machines replaced hard, physical human labor with mechanical labor. Today we have machines that operate other machines. Digitalization in manufacturing enhances productivity, optimizes production processes, and boosts the bottom line of manufacturers. Keeping pace with technology is crucial for business survival. Here is an overview of some manufacturing trends in manufacturing that Industry 4.0 players must watch to stay ahead of the competition.

What Are the Trends in Manufacturing?

3D Printing

3D printing is an additive manufacturing process that is changing the face of product creation. Although not a radically new but rather a maturing technology, it enables manufacturers to produce parts and prototypes quickly and inexpensively. 3D printing shrinks the time to market and decreases production costs.

Different manufacturing sectors have leveraged the capabilities of 3D printing in different ways. For instance, BAE Systems, a global defense, aerospace, and security company, used 3D printing technology to craft and certify a replacement part for a jet. The cost was 60% less than traditional manufacturing and reduced the production time by two months.

In the US, two out of three companies have begun to adopt 3D printing. Small businesses are incorporating 3D technology on par with larger enterprises (59% vs 75%). Last year, $414 million was spent on 3D printers with 79% of enterprises investing in this trend.

Cybersecurity

The era of Industry 4.0 is dependent on data and the interconnectivity of computers, machinery, processes, and products. Daily manufacturing operations are controlled and monitored via connected digital systems. However, digitalization of operational processes and infrastructure opens the door to cyber threats. Critical industrial systems and production lines are vulnerable to digital disruption and malicious cyber attacks. Like businesses in other sectors, manufacturers use online channels such as websites or online portals to capture new business opportunities and close sales. Any website downtime due to a cyber attack brings down the bottomline of the entire business, especially if the company relies on their website for eCommerce.

According to recent research by IBM, in 2015 manufacturing was the second-most attacked industry and cybersecurity remains a critical issue to follow. Manufacturers must constantly reinvent and upgrade their cybersecurity initiatives to protect the company’s servers against intruders and data breaches.

Predictive Analytics

Manufacturing has become smarter and more data driven. Vast sets of data can be captured and thoroughly analyzed to obtain actionable insights. Predictive analytics is another trend to watch in the manufacturing sector. This is a sophisticated approach to forecasting future events and their outcomes through data mining, statistics, modeling, and artificial intelligence. When ranking the future importance of advanced manufacturing technologies in last year’s Global Manufacturing Competitiveness Index, Deloitte put predictive analytics in a top position in the USA and ranked it fourth in Europe.

Through the implementation of predictive technology, manufacturing businesses can expect to improve their production environments and critical manufacturing processes. This includes

- Maximizing machine exploitation;

- Increasing product quality;

- Predicting equipment breakdown and its preventive maintenance;

- Increasing workplace safety;

- Reducing operational costs;

- Demand forecasting;

- Pricing improvement, and much more.

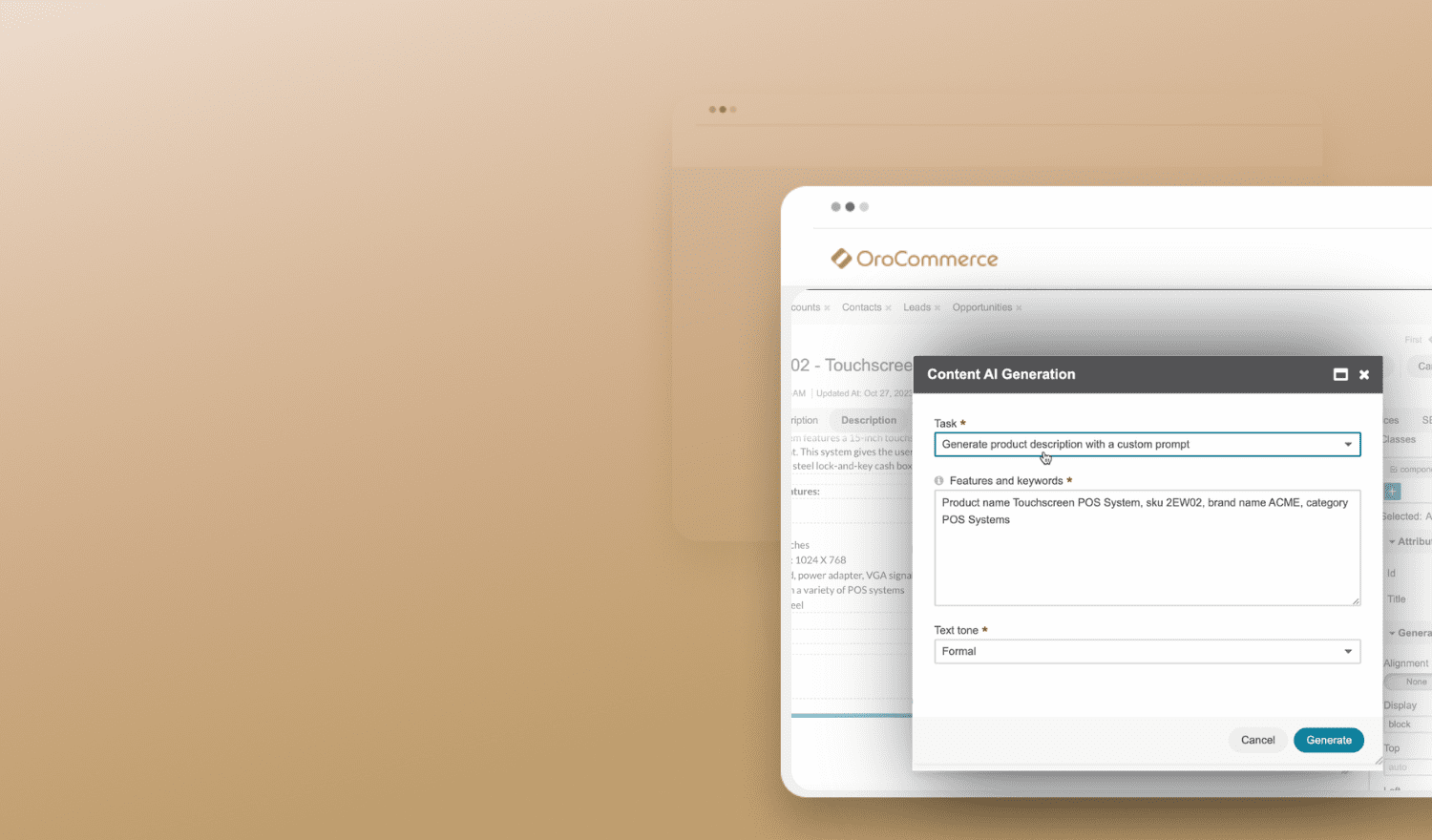

Artificial Intelligence (AI)

Artificial intelligence is the process by which intelligent computer systems perform tasks unaided by humans. It is among the leading technologies that are transforming manufacturing. It holds great potential, given that 70% of captured production data is currently unutilized. AI in eCommerce allows manufacturers to take advantage of the data captured from sales operations and consumers and act on it. By coupling AI with the Internet of Things, manufacturers can orchestrate and streamline business operations from computers to machinery.

AI technology is a natural fit for quality management, predictive machine maintenance, and supply chain performance enhancement. For example, AI-enabled machines equipped with smart sensors can predict and detect technical failures in real-time before the failure can impact the entire production process. AI has tremendous potential to avoid critical breakdowns by scheduling preventive repairs to save time and money.

Advanced Robotics

Science fiction movies tainted the robot image by depicting them as sinister machines rising against mankind. In reality, robots peacefully interact with humans and share workspace every day. By 2014, 59% of manufacturers were already using robotics technology to some extent. Today’s intelligent robots have powerful processors with the ability to automate manufacturing processes that once required human involvement. One in three manufacturers surveyed by Accenture is considering robotizing their facilities to automate operations. Advanced robotics and AI is expected to boost productivity across multiple industries by 30% while decreasing labor costs by 18-33%.

The very latest trend in advanced robotics is collaborative robots also known as cobots. Cobots are hot. These programmable systems offer an efficient way to automate the shop floor and improve quality assurance. Check out how GE Lighting leverage this technology and use cobots on the production line:

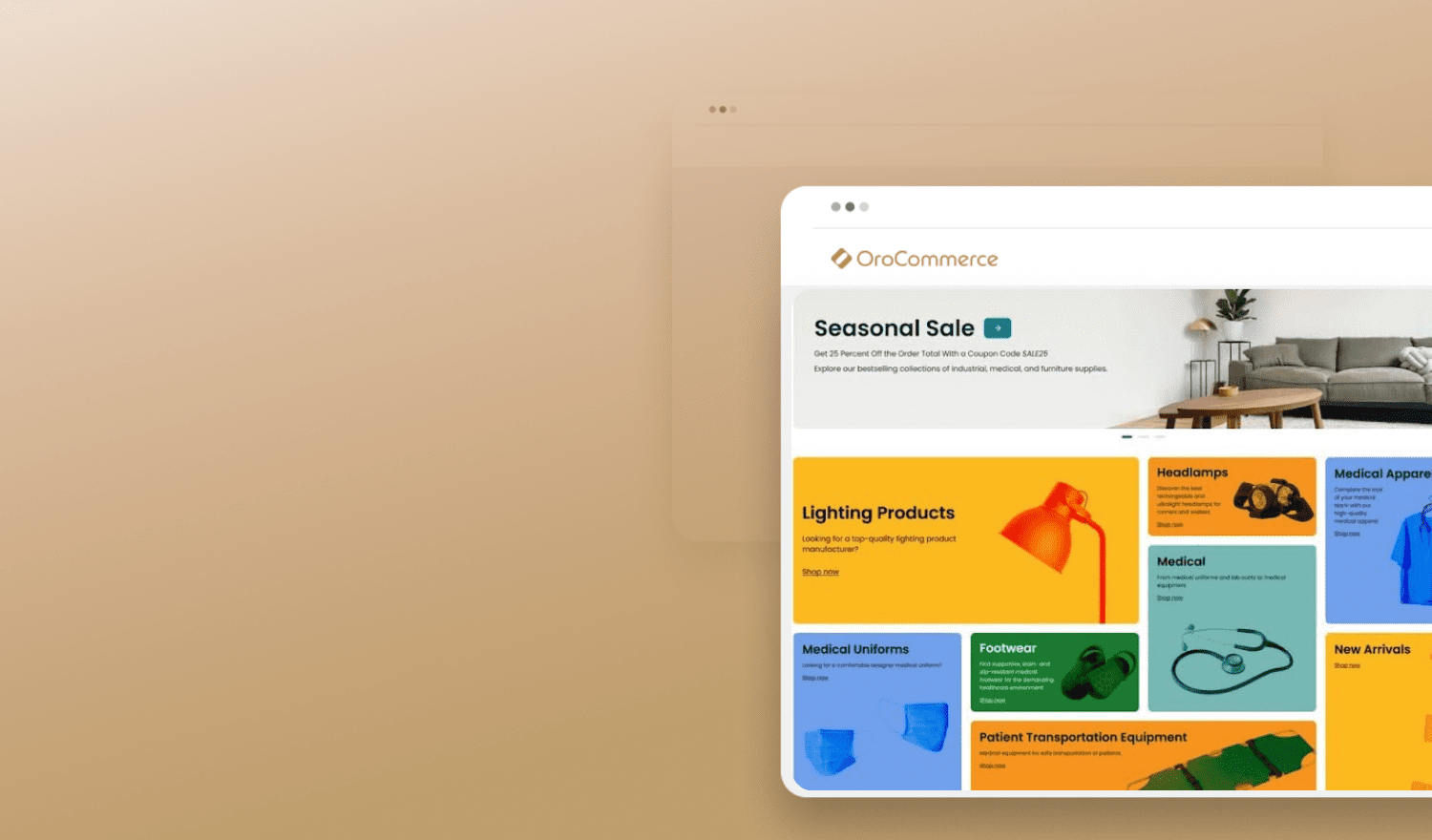

Cloud-related Manufacturing Trends

In manufacturing, short product development lifecycles and quick time-to-market are the holy grail everyone seeks. Cloud computing and cloud-based eCommerce software satisfy this insatiable need for the speed and change the way business operates. Some companies are already running cloud-driven manufacturing systems, but with the rise of Industry 4.0, the importance of hasslefree data sharing and streamlined business processes continues to grow.

By embracing end-to-end cloud software, manufacturers can set up and maintain the entire IT infrastructure with minimal investment. Manufacturing eCommerce systems deployed in the cloud can save up to 54% of expenses related to IT infrastructure, maintenance, and lifecycle for new and existing operational or process improvement projects.

In addition, cloud-based solutions designed specifically for manufacturers allow for better collaboration with partners and suppliers while minimizing the risk of sharing confidential data. Cloud technology has a high potential to be adopted by resellers, enabling manufacturers to improve supply chain efficiency.

Manufacturing Trends: Bottom Line

Evaluating and implementing the most impactful technologies is imperative for manufacturers to become future ready and stay future proof. Analyze these trends as follows to determine which is right for your business.

- Identify the areas to optimize using new technology. Forecast how this investment will elevate the business value of your products or services. Determine the extent to which the technology can improve performance and productivity.

- Compare the target value of performance to the cost of the technology implementation. Quantify the level of performance your company expects to achieve via a new technology and measure it against the investment costs. Consider the immediate tangible results of using the new technology. Project improvement results over time as the technology evolves. Factor in the development pace for the technology.

- Pinpoint the impact of the new technology on the entire organization. Anticipate how the innovation will influence the company’s culture. Are changes readily embraced by the staff? Will the new technology fit into the existing tech infrastructure?

Don’t take research for granted! A thorough manufacturing trends analysis will help you develop a complete roadmap for implementing any new technology.